Pramod Chaudhari's Blog

Friday, December 2, 2016

Wednesday, October 16, 2013

From uncertainty to stability

The RO system though leaves effluent streams as rejects. This reject too had to be prevented from going into the river. The court also instructed the textile industries to adopt a policy of zero effluents discharge.

Many technologies were implemented but none could solve the problem comprehensively. At this juncture, Praj was invited to provide a solution as part of the renewed efforts of the CETPs(Common Effluent Treatment Plant). Praj decided to take up this challenging application. This, we thought, would also help us add a new dimension to our water and wastewater business.

We took up the job of designing and installing an integrated 100 KLD (Kilo Litres per Day) zero liquid discharge system for the CETP. A multitude of efforts were put whole heartedly into the issue. This involved periodic collection and testing of effluent samples, study of existing effluent treatment plants, developing customized process and engineering solutions and demonstrating the efficacy of the solution on the 100 KLD plant.

The entire plant was designed, engineered, fabricated and erected by Praj on a turnkey basis. Finally, a successful commissioning was carried out for this 100 KLD plant. We are now working on two more projects for Tirupur based CETPs. The first one is for a 700 KLPD CETP and another for a 5000 KLPD in Sirupooluvapatti ,making it the largest installation of its kind.

The repeat orders of progressively increasing capacities certainly show a great deal of trust in our technology which was, undoubtedly, borne out of the successful working of the first plant.

The first project led us to venture into a challenge zone. With the experience of designing many plants and a streak of intrapreneurship, the seemingly tough proposition soon turned into a cause for celebration; not only for us but also for a number of textile units that had found the going tough in the face of the court orders. The effort played an important role in getting jobs back at some of the units.

Certainly, for an engineer and an engineering company, nothing could‘ve been more satisfying!

Friday, September 13, 2013

2nd generation Cellulosic Ethanol Demo Plant - Breaking new ground

Two weeks ago, we broke ground on our 2nd Generation, Cellulosic Ethanol Demo Plant. It was significant in more ways than one. It is one of the first plants of its kind in South East Asia. It is a testimony to the ingenuity of Indian scientific temperament and intellect. It is also a major leap in Industrial Biotechnology Application to a very real and present challenge – that of environmental pollution due to transport fuels.

In India, we have been advocating fuel ethanol blending with gasoline not just for environmental purpose but also for hedging against runaway gasoline prices. Today, as we face the prospects of high foreign exchange rates and consequent impact on Current Account Deficit etc. it becomes even more relevant to create new paradigms in energy.

With a mere blending of 5%, India stands to save Rs. 650 crore for the exchequer.

Worldover, 80% of ethanol is used for blending with gasoline/petrol. So, there is a lot of learning which is available.

One such learning which we have addressed is that of food vs. fuel. And, that is exactly what the demonstration plant will be working towards. Providing vital data to ensure that various non-food biomass (agri residue) like corn stover, cobs and bagasse can be converted into liquid fuel like ethanol. This not only adds value to the agriculture biomass, but it also ensures that there is a wider choice for feedstock.

However, I am truly excited about the fact that this demo plant will also be a starting point for many biochemicals development route. Biotechnology has enabled us to replace many hydrocarbon origin products with carbohydrate or biobased products. The best example is Bioplastics. It is also a big leap of faith for Industrial Biotechnology. We are familiar and aware of BioPharma as a discipline. Very few are familiar of Industrial Bitoech because it is yet to achieve critical mass. But, it has the power to shake the world, creating a bioeconomy. I am glad that Praj has been able to show that India too can pave the way in the new BioEconomy. After all, we have 0.17 mln people pursuing research science in India. It should show somewhere.

And, a final word to my detractors. It is nice having you around. We have long way to go together.

In India, we have been advocating fuel ethanol blending with gasoline not just for environmental purpose but also for hedging against runaway gasoline prices. Today, as we face the prospects of high foreign exchange rates and consequent impact on Current Account Deficit etc. it becomes even more relevant to create new paradigms in energy.

With a mere blending of 5%, India stands to save Rs. 650 crore for the exchequer.

Worldover, 80% of ethanol is used for blending with gasoline/petrol. So, there is a lot of learning which is available.

One such learning which we have addressed is that of food vs. fuel. And, that is exactly what the demonstration plant will be working towards. Providing vital data to ensure that various non-food biomass (agri residue) like corn stover, cobs and bagasse can be converted into liquid fuel like ethanol. This not only adds value to the agriculture biomass, but it also ensures that there is a wider choice for feedstock.

However, I am truly excited about the fact that this demo plant will also be a starting point for many biochemicals development route. Biotechnology has enabled us to replace many hydrocarbon origin products with carbohydrate or biobased products. The best example is Bioplastics. It is also a big leap of faith for Industrial Biotechnology. We are familiar and aware of BioPharma as a discipline. Very few are familiar of Industrial Bitoech because it is yet to achieve critical mass. But, it has the power to shake the world, creating a bioeconomy. I am glad that Praj has been able to show that India too can pave the way in the new BioEconomy. After all, we have 0.17 mln people pursuing research science in India. It should show somewhere.

And, a final word to my detractors. It is nice having you around. We have long way to go together.

Thursday, May 23, 2013

Industry Academia partnerships: A symbiotic bond

I was recently invited to speak at a seminar organized by IIT, Bombay and Washington University in St. Louis (WUStL) to discuss ways in which corporate leaders can benefit from partnerships of the kind that exists between IITB & WUStL. In this blog, I lay forth my views on a collaboration that has been an endearing thought to me, and some ideas which were expressed by me at the seminar.

I was recently invited to speak at a seminar organized by IIT, Bombay and Washington University in St. Louis (WUStL) to discuss ways in which corporate leaders can benefit from partnerships of the kind that exists between IITB & WUStL. In this blog, I lay forth my views on a collaboration that has been an endearing thought to me, and some ideas which were expressed by me at the seminar.There is a potent bond, which if nourished well, could creatively transform the corporate world. I am talking about the Industry- Academia bond. Let me first dwell a little on why I feel that the collaboration could hold the key to many of our challenges ahead.

The academic world, by its very nature, is a place that fosters creativity. It provides the inspiration, freedom and space to bring forth new ideas. The industry, on the other hand, gives these ideas direction and a suitable platform to be introduced to the world. There is a need for bright ideas to reach the market and be protected thereafter. Similarly, the industry needs talent and the wisdom of the academia. There has to be a good blend of intellect with commerce. But, for research to be fruitful, focus is very important. And, this is where industry defined projects are of immense help, since they reduce the time to market significantly.

So the next logical question is, how do we accomplish such an alliance. Over the past few years, this collaboration has been gaining momentum and I am aware of many models that have emerged, especially financial. Finance, no doubt, is a very critical spoke of this collaboration wheel. However, there are other not-so-obvious aspects that make such partnership imperative. A recent trend that has cropped up and that to me holds a great deal of interest is Crowd Sourcing.

As part of crowd sourcing, companies sometimes outsource a specific problem or a project to external agencies. The external agency I talk of in the context of this blog is academia. On the one hand the academia gets to exercise their creative faculties, while on the other, the industry gets appropriate solutions.

There have been several instances when gems (ideas) that have revolutionized industry have been conceived in the world of academia. ENIAC (widely acknowledged to be the first successful high speed electronic digital computer) was initiated at a university campus in USA. Facebook, the largest social networking service, was launched while the founders were still on the university campus. The foundation of APPLE too was established in a college campus.

Another important aspect to be considered is the Energy and Environment domain. It needs to be nurtured much in the same way that IT or Communication have been in the past. It brings many faculties to the fore, right from Biotech, Chemistry, Material Science, Engineering to Life Sciences and many more. Often, this in itself is a challenge for companies which are either Engineering, Biotech or Life Sciences Companies. From my personal experience I can tell you that it is very difficult to engage such multifarious skill sets within the same organization. First, talent acquisition becomes an issue and then the infrastructure is a challenge. At Praj, we have to constantly balance out the requirements of each of the streams because we are an amalgamation of biotech, chemistry and engineering. Much of the work can be incubated at the academia level and later ported into the corporate world to ‘take to market’. This is good for the investors too, because they get better visibility. Environment and Energy, especially alternate and clean energy, where much of the developmental work is focused, is not completely understood by the financing world and regulators. The Industry-Academia network can be of tremendous help in bringing concepts into better focus so that the solutions can be better related to business paradigms.

About 75 % of the Indian companies today fall in the MSME sector. Innovation is often slow in such companies as they cannot always attract the right talent. If such companies can prudently bring Industry-Academia partnership into practice, they'll find a lot of viable solutions coming their way, whilst providing the academia a ready opportunity to work on practical problems.

There are more advantages of Industry-Academia collaboration than meets the eye. More and more industries and academic institutions need to adopt this practice. Nurtured well, it has the potential to become a symbiotic relationship that could elevate both the partners and bring more meaningful progress to both.

Tuesday, April 23, 2013

Thailand : A Prudent Approach to Ethanol Blending

|

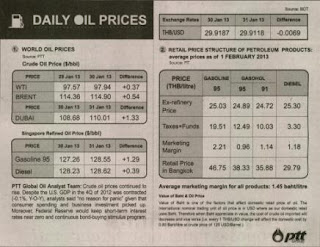

| Pic 1 - Price comparison |

|

| Pic 2 - Transparency in prices |

This made me think how Thailand succeeded in implementing an Ethanol Blending Program, while countries like India continue to struggle. Both India and Thailand are democratic countries. Both have oil Companies which are largely state owned. But Oil Companies seem to have completely embraced the program in Thailand, where they regulate the price of ethanol as per the policy.

What is so special about Thailand’s Ethanol blending policy?

It is a policy which is based on taking all stakeholders on board, be it the Oil Companies or the consumers, with particular emphasis on the consumers. If you see pic1 and pic2 you will notice the transparency in the information shared with the public. The consumers know how the final price of Gasoline is determined, based on International crude price, taxes and duties. They know the relationship between the oil barrel price and Gasoline. Also, it is evident that they will end up paying much lesser if they choose Gasoline with a higher percentage of Ethanol.

At the back end, the purchase price of Ethanol is determined by the import parity price of Petrol and the price of imported Ethanol. From April 2013 onwards, the price of Ethanol will be determined by the input cost which will ensure steady supply through better viability for Ethanol producers. Apart from that the Agriculture Ministry is also ensuring that adequate feedstock is available for local ethanol producers through efficient cultivation of cassava and sugarcane, from which ethanol is derived. This is indeed very pragmatic where the entire chain of input and output is made viable, so that everyone derives benefit from the program.

Incidentally, Thailand is a large producers and exporters of chemicals. At this point, there seem no resistance from the chemical manufacturers or automobile companies.

Where did a nation of 66 million people get the courage to lead the alternative fuels program? As a nation of 1200 million with an oil import bill of US$ 140 Billion , it has taken India a fairly long time to get to 5% blending, which is scheduled for June 2013 (after a long hiatus).

Perhaps it is time for us to really see the woods for the trees?

Tuesday, January 17, 2012

Me & Praj Industries

I believe a Company should be run as we would run our lives, with its joys and sorrows. It is a living organization made up of living beings. It should reflect the values of transparency, respect and creativity through its life-time.

I founded Praj Industries when I was 35 years old. That means I spent a better part of my life as a member of Praj. Today, Praj and my identity has got totally meshed. It is a living organization with people, eco-system, values, ethos that are also part of me. I have enjoyed every moment of being a part of Praj and Praj being a part of me. Recently, we appointed Gajanan Nabar as the new CEO & MD of Praj. While I continue to be engaged as the Executive Chairman, I expect him to take on more and more of the operational responsibility in due course. I am actively involved in the strategic aspect of the Company and as the guardian of the three capitals - Human, Reputation and Financial. As the founder and the pioneering member, Praj is an essential part of my existence and I value all relationships that I have created through the Company - Employees, Customers, Associates, Suppliers and Peers.

I founded Praj Industries when I was 35 years old. That means I spent a better part of my life as a member of Praj. Today, Praj and my identity has got totally meshed. It is a living organization with people, eco-system, values, ethos that are also part of me. I have enjoyed every moment of being a part of Praj and Praj being a part of me. Recently, we appointed Gajanan Nabar as the new CEO & MD of Praj. While I continue to be engaged as the Executive Chairman, I expect him to take on more and more of the operational responsibility in due course. I am actively involved in the strategic aspect of the Company and as the guardian of the three capitals - Human, Reputation and Financial. As the founder and the pioneering member, Praj is an essential part of my existence and I value all relationships that I have created through the Company - Employees, Customers, Associates, Suppliers and Peers.

Wednesday, November 25, 2009

Copenhagen Climate Change Summit

I shall be leaving for Copenhagen for the Climate Change Summit very soon. Climate Change is not an agenda for individual nations or interest groups, but for the entire world. On my sixty-first birthday, I would like to engage with all of you to get your views and thoughts on this important milestone in the history of planet earth.

Subscribe to:

Posts (Atom)